Air Dryers

• Heatless Dryer: operates with pressure swing adsorption technology, and it is the most common type of dryer suitable for various industries. Ideal for minor and medium-flow air treatment, correctly sized and regulated can easily reach extreme dew point levels.

Sinergia has experience in this technology since 2006. Fully packaged units, provided with an in-house developed unit control system (UCP), can now be supplied in various configurations: Sinergia standard design, improved for heavy-duty and severe ambient installation and hazardous or explosive environmental conditions.

• Heat dryer with blower: a pressure swing adsorption type part of the hot regenerated family. It is frequently used for large capacities employing an external heater (electrical or steam type) to increase adsorbing material’s regeneration via reducing dry air consumption.

The added presence of a blower increases the efficiency of the dryer by dropping further the purge air.

• Heat of compression dryer: adsorption dryer with hot regeneration in closed circuit version.

It uses the heat of compressed air-stream (aftercooler of air compressor is by-passed/excluded) to regenerate the adsorbing material. This type of equipment is fit for a large amount of airflow with the benefit of not necessitating any external energy source and consuming little purge air.

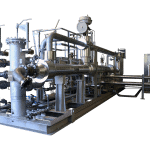

• Refrigeration Dryer: Sinergia manufactures packaged refrigeration systems as an alternative technical solution for water content reduction in compressed air. This is accomplished due to the composition of the water chiller, primary heat exchanger, economizer, condensate separator, and functionally integrated to cool down the compressed air-stream and separate the condensed water to design level (+3°C max. dew point).

It can be manufactured and certified as per ASME (U Stamp) – TEMA C – TEMA R.

For additional information or enquiries, please contact us.